ZINCALUME® steel: A high-performance anti-corrosion coating

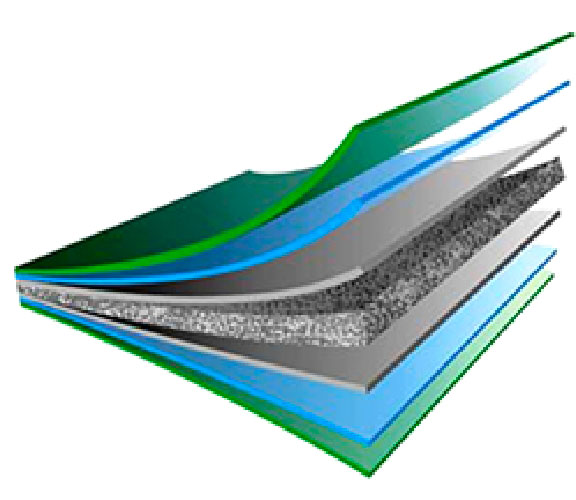

- ZINCALUME ® AZ150 metallic coating:

corrosion protection. - Steel base :

mechanical strength. - ZINCALUME ® AZ150 metallic coating:

corrosion protection.

Its technological license has been resold in many countries, and ZINCALUME® is now the benchmark steel for corrosion resistance, particularly in marine environments.

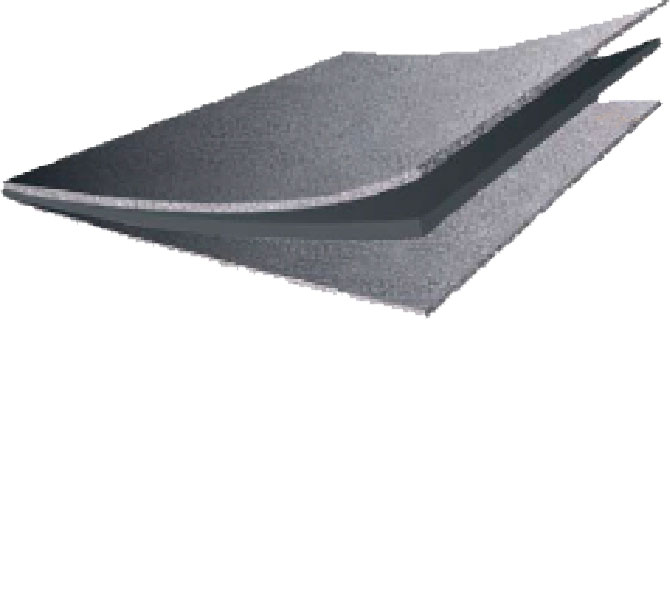

ZINCALUME® steel is coated with 150 g/m² of zinc-aluminium alloy (AZ150) on both sides as standard. It is protected from atmospheric corrosion by the two intrinsic properties of zinc and aluminum:

A protective barrier: the zinc/aluminium coating itself insulates the steel from the corrosive environment, as it is resistant and non-porous.

Sacrificial protection: steel exposed in uncoated areas (scratches, cut edges, holes) is protected by the sacrifice of nearby zinc.

For additional corrosion protection, a paint coating adapted to the Caledonian climate can be applied to the ZINCALUME® substrate.